The park of CNC machines, already in place at MOB for many years (2 HSM 3 axis and 2 HSM 5 axis – including 1 equipped with a load/unload robot) has been supplemented in recent months by a fifth 5-axis machine. This is a DMG MORI CMX70U ...

The company « Moules et Outillages de Bourgogne » specializing in the study and design of tools for the investment casting is located in the Saôneor area since 2015. Throughout its development, it has attached itself to a real desir...

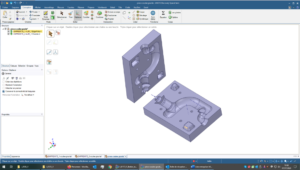

To produce tools for the investment casting, a specialty of « Moules et Outillages de Bourgogne », the “study and design” phase is of course essential (see our article of last month https://moules-outillages-bourgogne.com/en/zoom...

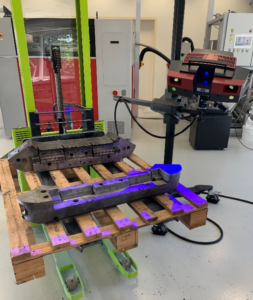

« Moules et Outillages de Bourgogne » company, specializing in the design of tools for the investment casting, provides its customers with its skills and equipment to offer reverse engineering operations. A concrete example ? Our cli...

« Moules et Outillages de Bourgogne » company specializing in the study and design of tools for the investment casting is developing its machining activity. Equipped with a machine park comprising: 2 3-axis UGV (HURON K2X10): capacit...

Moules et Outillages de Bourgogne specializing in the study, design and manufacture of tools for the investment casting and the injection of wax models is now equipped with all the technologies enabling reverse engineering of a part to r...

In order to expand its service offer, Moules et Outillages de Bourgogne, a company specializing in the study, design and manufacture of tools for the investment casting and the injection of wax models, has acquired a new CAD software cal...

“Moules et Outillages de Bourgogne” company, which specializes in the design and manufacture of molds for the investment casting foundry, has a 7-person design office entirely dedicated to engineering. In fact, all of our designers, ...

The company Moules et Outillages de Bourgogne, specialized in the design and manufacturing of dies and fixtures for the investment casting foundry, is developing 3D printed wax casting molds! The 3D printing workshop of Moules et Outilla...

Moules et Outillages de Bourgogne, a mold maker specializing in the investment casting, is pleased to announce that it has obtained ISO 9001 certification when the quality audit was carried out on 03/05/2020. Through this certification, ...

Through this note, I wanted to inform you of the new directives taken within our society, to better manage our activity despite the measures related to the fight against the epidemic which strikes us today. First, all the actions impleme...

The company “Moules et Outillages de Bourgogne”, specialized in the design of tools for the investment casting and the injection of wax models, has a workshop specially dedicated to 3D printing. Originally, this workshop was dedicate...

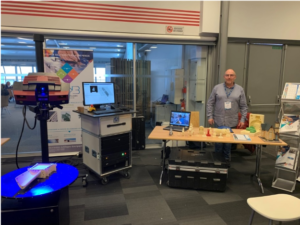

For the second time, « Moules et Outillages de Bourgogne », specializing in the design of tools for the investment casting, participated in the CPME annual professional fair to promote its new 3D equipment (3D printing, 3D scanning ,...

Moules et Outillages de Bourgogne gets a 3D scanner with it’s 3D printer

11 January 2020News, EnglishIn order to complete its offer, “Moules et Outillages de Bourgogne”, specialist in the design of molds for the investment casting, invested at the same time as 3D printing in a 3D scanner. The ATOS Triple Scan currently in service in our...

Since May 2019, « Moules et Outillages de Bourgogne » is equipped with a 50 tons press, allowing us to validate the closing quality of our molds in the best possible conditions. In addition, our desire being to best meet the requirem...

Moules et Outillages de Bourgogne at the Micronora 2018 tradefair in Besançon

15 October 2018News, EnglishMoules et Outillages de Bourgogne participated, with 13 other companies from the region, in making a human bust through 3D imaging, so as to contribute to the promotion of 3D printing in Burgundy-Franche-Comté. This project, initiated a...

Additive manufacturing is a technology that has been developing at an increasing speed for the last few years in all fields and especially in industry. Laser fusion, resin polymerisation, Fused Deposition Modeling, powder bed printing…...

After several months of technical and financial studies and in collaboration with the CETIM (Technical Centre for Mechanical Industry) on the one hand and the support program, ‘Robot Start for Small and Medium sized companies’, the c...

Seven months have passed since our move, the machines are in place, the personnel on their marks. It was time to think about sharing our enthusiasm by officially opening our new factory. Everyone was involved in the event and nearly 15...

Mr Pierre GATTAZ, president of MEDEF, in a visit to Moules et Outillages de Bourgogne

3 December 2015News, EnglishThe paint was hardly dry and we had only just moved into the offices and workshop, when we had the great pleasure of welcoming Mr Pierre Gattaz, the boss of bosses. He came to Chalon-sur-Saone on December 2, 2015 for the 7th economic for...